Precision Measurement with Air Gaging

In precision manufacturing, accurate measurement is crucial. Air gaging, or pneumatic gaging, uses compressed air to measure workpiece dimensions with high precision, making it ideal for industries like automotive, aerospace, and machining.

Benefits of Air Gaging

Speed and Efficiency: Fast measurements with minimal setup.

Accuracy: Measures tolerances down to the micron level.

Non-Contact Measurement: Prevents damage to delicate parts.

Ease of Use: Simple operation and minimal training required.

Kao Metrology's Air Gaging Devices

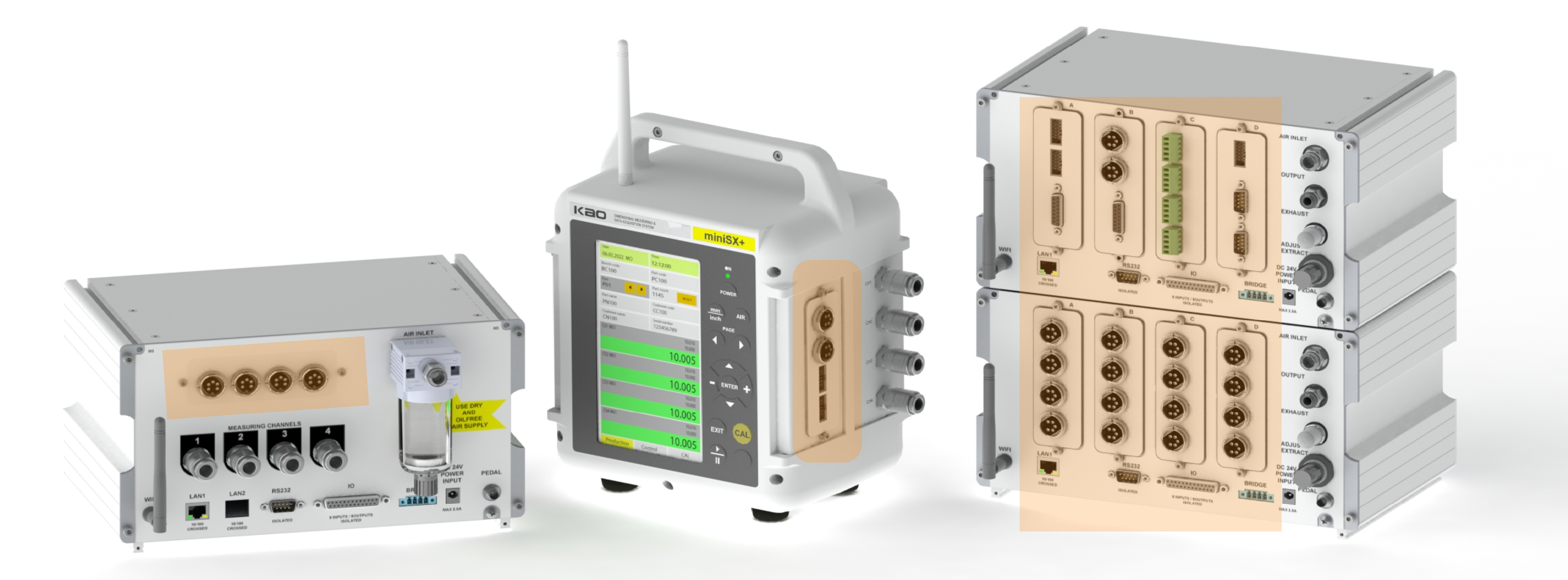

Kao Metrology leads in air gaging technology, offering high-performance devices like the MiniSx+, KA0X, KA100, and KA200.

KA100 4 Channel AirGage

- Features: High-resolution measurement and multiple/single channel display.

KA200 8 Channel AirGage

- Features: Advanced model with enhanced memory and connectivity options.

KA0X 2/4 Channel AirGage

Features: Multiple channel display, part counting, and TCP data sharing.

Integration: Seamless with PLCs and robots.

MiniSx+ 4 Channel AirGage

Resolution: 0.1µm

Memory: Stores 100 parts, 100 measurements, and 10,000 records.

Connectivity: USB, RS232, and wireless Ethernet.

Ease of Use: One-button calibration and internal regulators.

Conclusion

Air gaging is essential for precise measurements in manufacturing. Kao Metrology's devices offer accuracy, reliability, and ease of use, ensuring your components meet the highest quality standards. For more information or to enhance your measurement capabilities, contact Kao Metrology today.