Measurement of parts is sometimes carried out in a workshop with a single pneumatic device. Sometimes there may be situations where a large number of measurements are required. Measuring multiple dimensions of a part simultaneously will shorten the measurement time. Sometimes, proper positioning of the part is required to ensure measurement accuracy. Sometimes, geometric tolerances come into play. Not only diameter but also factors such as ovality, cylindricity, and taper may be required. In such cases, probe design is important. Do not hesitate to consult us, whether it is to measure a single diameter or 5 diameters. We have services in this regard.

GET A QUOTE

We offer the best products and the services to our customers and the distributors all around the world.

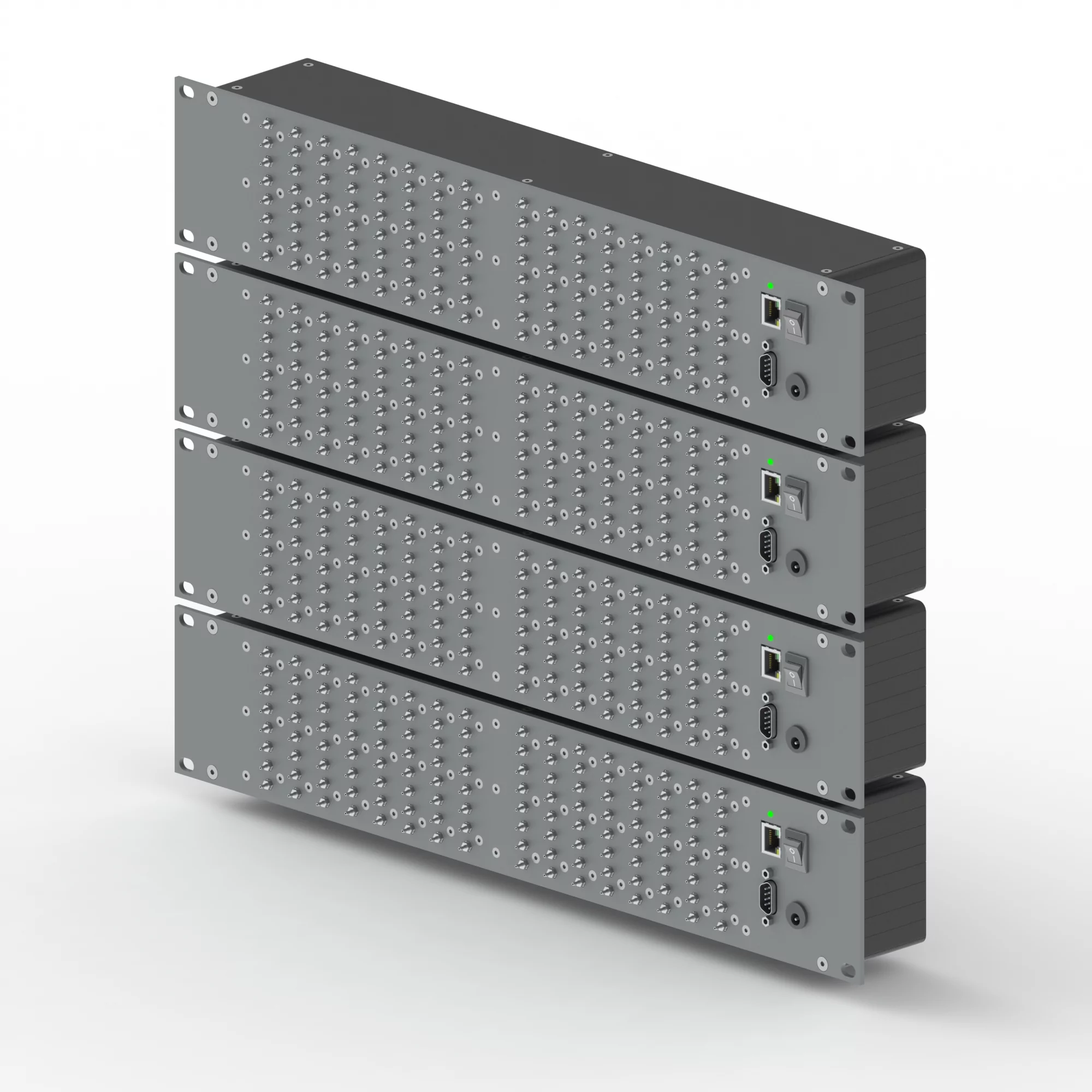

All KAO measurement devices record data, store them in their internal memory, and list the records on their screens. However, in some applications, it is desired to transfer this data outside the device.

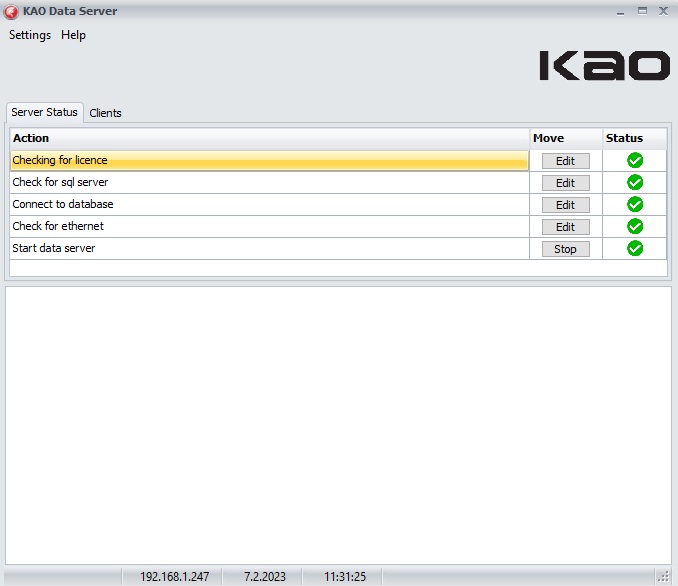

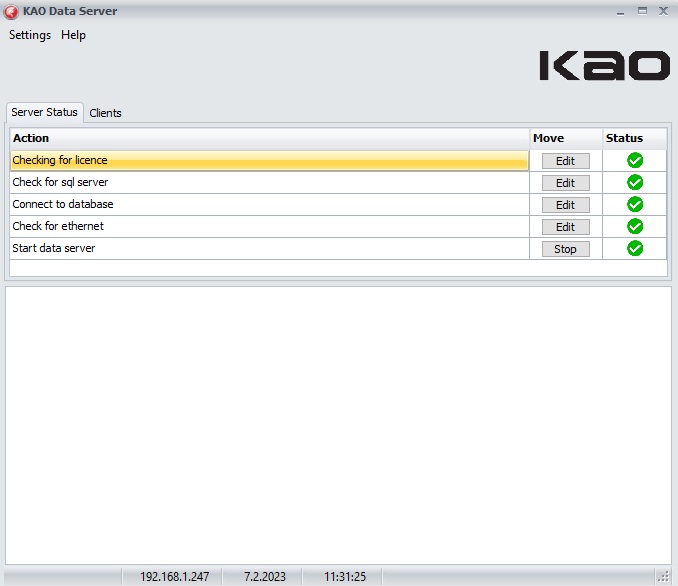

The DS software serves as a server allowing wired and wireless KAO devices to exchange data using TCP and UDP protocols. It synchronizes the date and time settings of devices with a computer. The wifi router and password for devices in the field are provided. Devices are registered on the QSPY server screen with their serial numbers. The QSPY server automatically assigns IP addresses to devices. QSPY DS establishes its own database using the Windows SQL infrastructure. It records the data received. All operations occur without user intervention. Devices determine data variables.

Provides real-time access to data stored in SQL server. It displays them on screen and exports them to printers in the form of lists and graphs.

When data reaches DS, it classifies them with catalog numbers. It prepares them as dfq extension files in the designated folder according to the qdas precellla protocol. All operations occur without user intervention.